automatic capsule filling machine working principle

The machine shall be tested before being filling capsules The operator is required to be familiar with this manual and well know the performance of every machine part and the. Ad Wide range of capabilities from sterile injectables to solid dosage form products.

Capsule Filling Machine The Blueprint Guide Saintyco

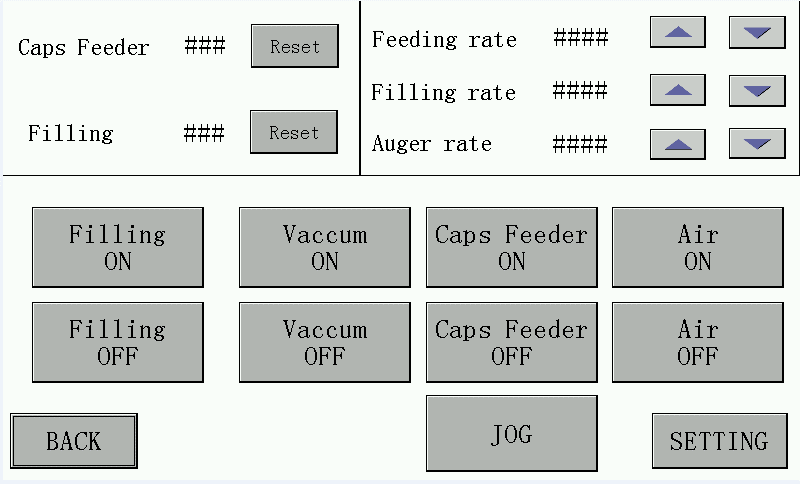

6 holes for 9 holes for 1200C 18 holes for 2000C and 24 holes for 3500C.

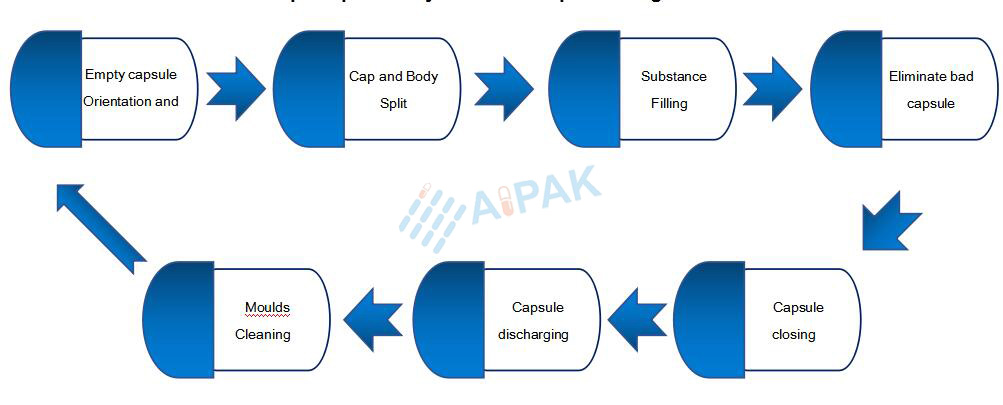

. It can be done by a number of different. Working Principle of Capsule Filling Machine. Working principle of automatic capsule filling machine.

SaintyCos top selling products include. After that the material is filled in. Automatic capsule filling machine is a very important machine in pharmacy industry.

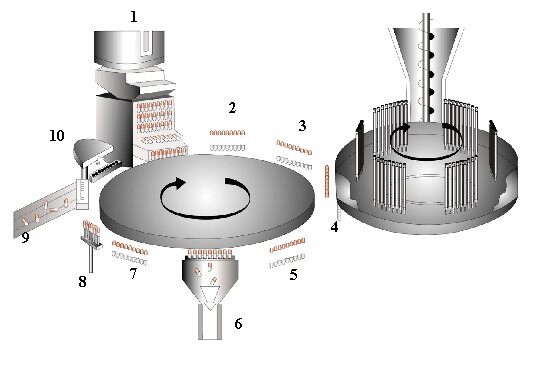

Save Time And Encapsulate Your Own Supplements On The Go Like A Pro. Put the lower mold to the turntable and add the. Fully automatic capsule filling machine semi-automatic capsule filling machine and manual capsule filling machine.

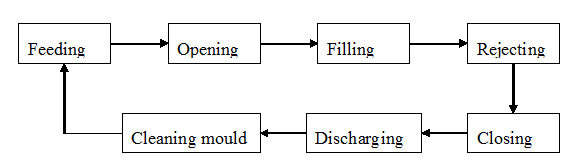

The body of the capsule is transferred to the filling station where the active ingredients are filled in the capsule. I will discuss all the three working principles of automatic encapsulation machine here. 1 Atmospheric pressure method is also called the pure gravity method that is under normal pressure the liquid material flows into the packaging.

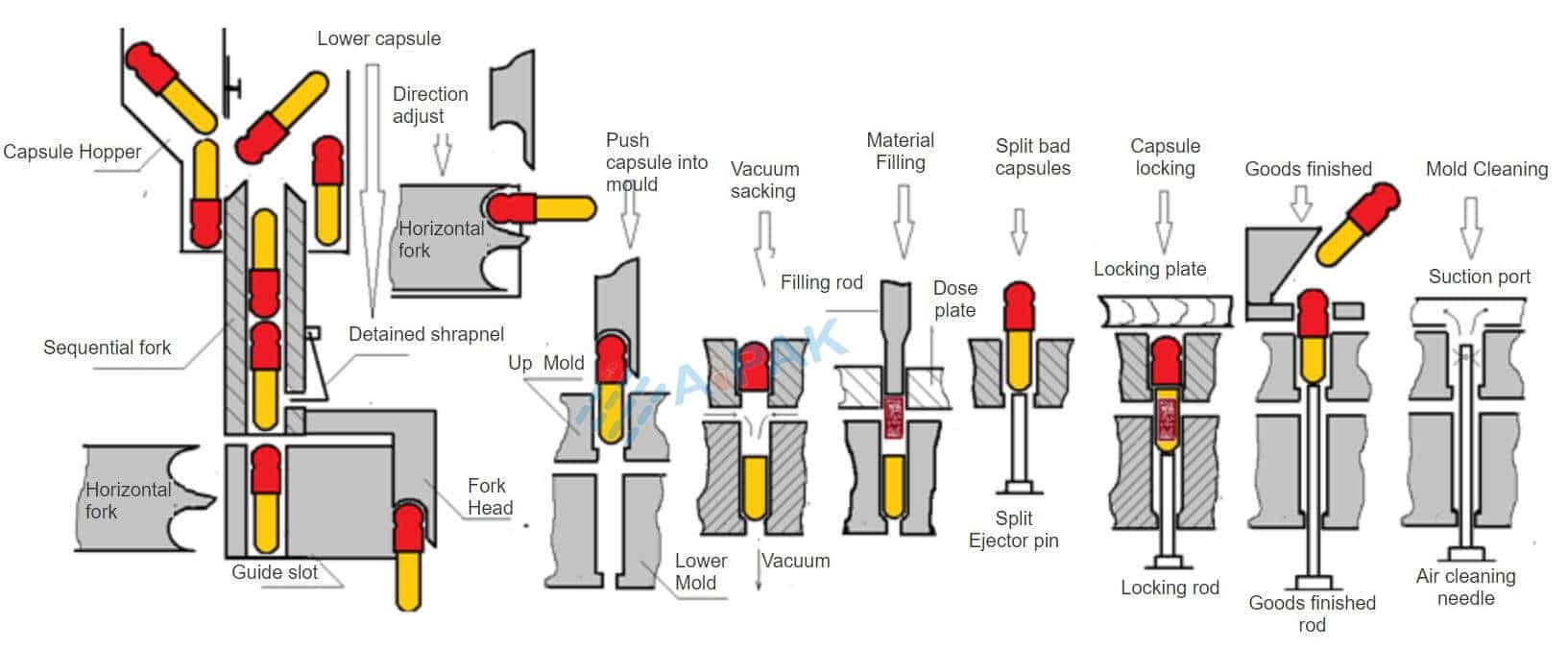

Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. Take our NJP series automatic capsule filling machine as an example. The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork.

New closed structure in line with GMP. Stable operation safe and reliable. SaintyCo manufactures all types of capsule filling machines including tamping pin capsule filling machine automatic capsule filling machine semi-automatic capsule filler and more.

Working Principles of Various Filling Machines. Liquid Filling Machine Its Principles. Aipak automatic capsule filling machine can fill empty capsules with various substances including medicine or nutrientsThe automatic capsule filler can fill different size of capsules.

Aipak automatic capsule filling machine working principle. 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by. The liquid filling machine works when the pressure is high.

Ad Designed To Manually Fill Your Empty Capsules With Various Supplement Ingredients. This can be classified as liquid pressure. Filling method of the filling machine.

Ad Connecting buyers and sellers of commercial industrial equipment for 20 years. We connect buyers to the equipment they need easier and faster than they can on their own. This section is the empty capsule feeding mechanismwhich is to load the empty capsules into the mold for the next procedure.

Capsule filler is a type of machine used to fill empty capsules with pharmaceutical ingredients. The capsule filling machine is an automatic capsule filling machine by which the separation filling and sealing of capsules can be carried out automatically. During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous.

Batch sizes can range from a few hundred to tens of thousands of dosage units. Batch sizes can range from a few hundred to tens of thousands of dosage units. First the capsule caps are divided from their bodies.

An automated filling machine will take care of the entire filling process itself. The capsule filling machine work on certain principles. These capsules fillers are divided into 2 categories depending upon their uses ie personal.

Ad Wide range of capabilities from sterile injectables to solid dosage form products. Capsule Filling Machine Fully Automatic is highlighted in this Working Animation Project which explains Capsule Filling Process and gives detailed presentati. The principles of the machines are as follows.

If you run a large scale production firm then using automated capsule filler is a must. It shows how many capsules. For capsules with good quality the machine can be run fast while the machine shall run relatively slowly if the capsule quality is not good.

This can be done manually or with the help of an automatic capsule filling. Request A Quick Quote. The principle of the fully automatic hard capsule filling machine is that when the equipment starts running the capsules in the capsule hopper will enter the main board assembly vertically.

Pharmaceutical processing is a series of steps and capsule filling is an important part of the process.

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Semi Automatic Capsule Filling Machine Manual Working Principle Ipharmachine

Semi Automatic Capsule Filling And Packaging Machine Cgn 208 D Riempitrice New Type Manual China Capsule Filling Machine Manual Made In China Com

How Different Types Of Capsule Filling Machine Work By Lodhapharma Issuu

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine Working Principle Ipharmachine

Njp800 Industry Big Automatic Capsule Filling Machine China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

Automatic Capsule Filling Machine Working Principle Ipharmachine

Tamping Pin Type Capsule Filling Machine Working Principle

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

How Different Types Of Capsule Filling Machine Work

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

Automatic Capsule Filler Encapsulation Machine Njp 1200c Ipharmachine

Encapsulators Operating Principles Types And Sequence Of Events

Semi Automatic Capsule Filling Machine Saintytec